AEB tests lead free aluminium alloy 2033

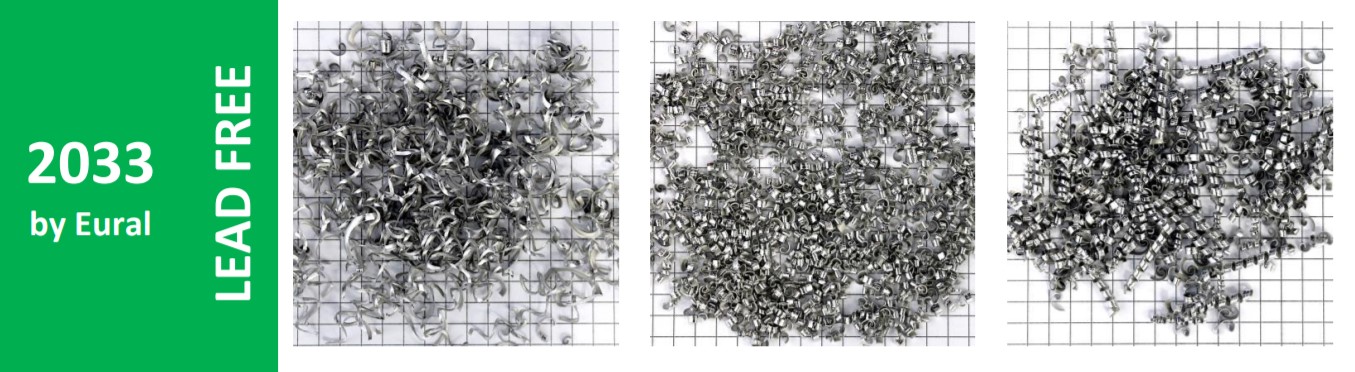

Over the past year, together with its trusted aluminium supplier, A&B Torneria has carried out some machining tests with the new lead free aluminium alloy 2033 developed by EURAL – a new solution for high speed automatic lathes. This new alloy helps increase machining parameters, reducing cycle times thanks to its excellent chip forming performance, without losses on machinability and part finishing.

Considered dangerous for human health and for the environment, lead came under the spotlight of the European regulatory bodies resulting in EU restricting rules on the use of hazardous substances in electrical and electronic equipment to protect the environment and public health (RoHS) which has led EURAL to develop LEAD FREE aluminum alloys.

A&B and EURAL technicians met at A&B’s headquarter to analyze the results of some production trials – an occasion for EURAL to directly check and discuss A&B’s feedback to their new material – a new solution to meet market and machining companies needs. A&B knowledge and expertise within the turning world met EURAL’s new material bringing innovation to the industry and the market future.

A&B Torneria benefits from its proximity to most of its suppliers, all of them based within the Brescia province, a flourishing and innovation-driven region. Among these suppliers there is EURAL – leader in the sector of semi-finished aluminum products, being just a few minutes away from A&B’s headquarters.

Such proximity is an extremely positive factor for the sourcing strategy of A&B for raw materials, services and, like in this case, for the R&D.