A&B’s highway to automatization

As you may have noticed from our last shared news, material- and machine-wise, here in A&B we have paid great attention to our continuous modernization. Market – and therefore our client’s needs are our main drive for persistent R&D. Together with our clients we’ve developed several solutions to optimize some of the most challenging aspects related to production and assembly.

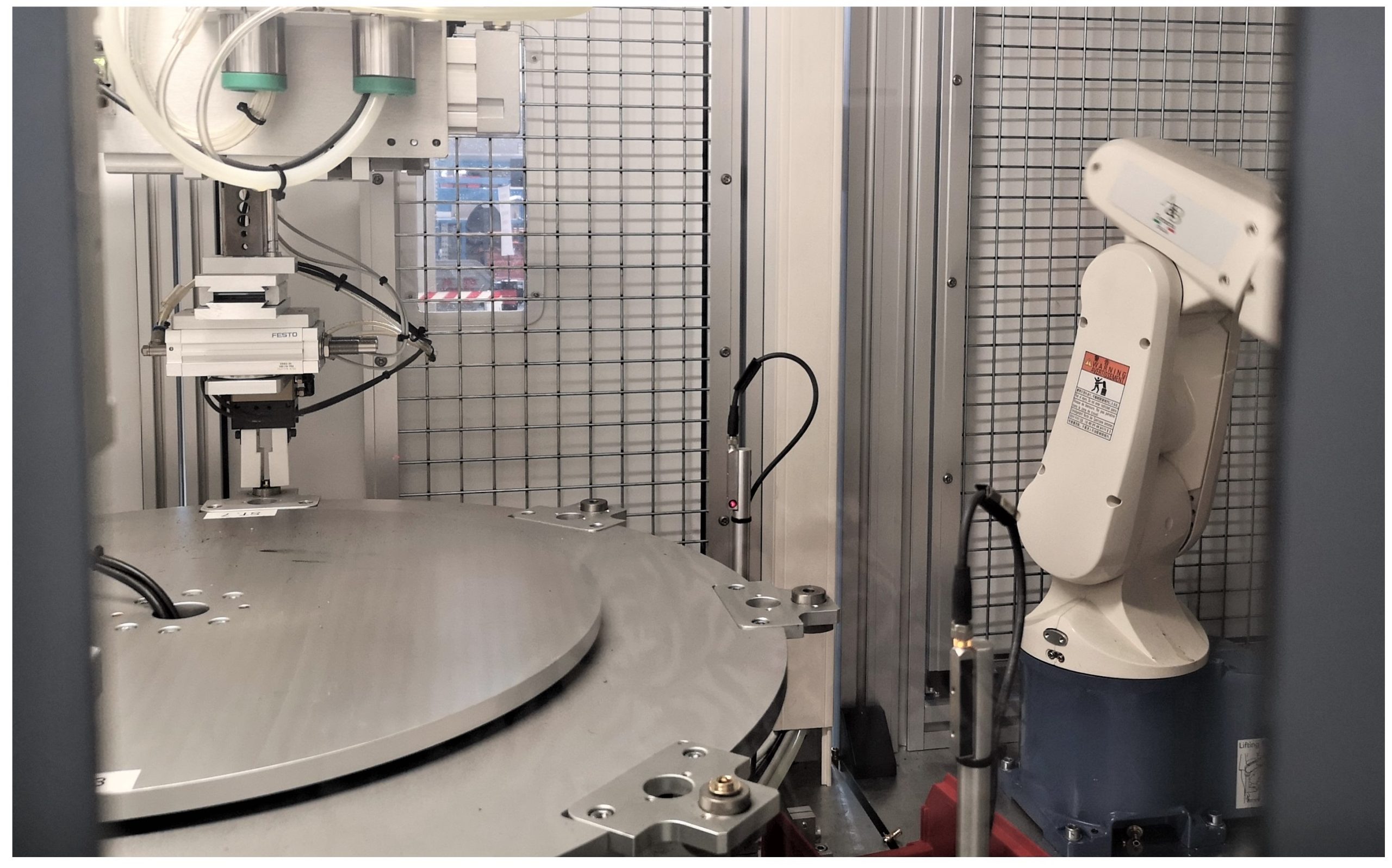

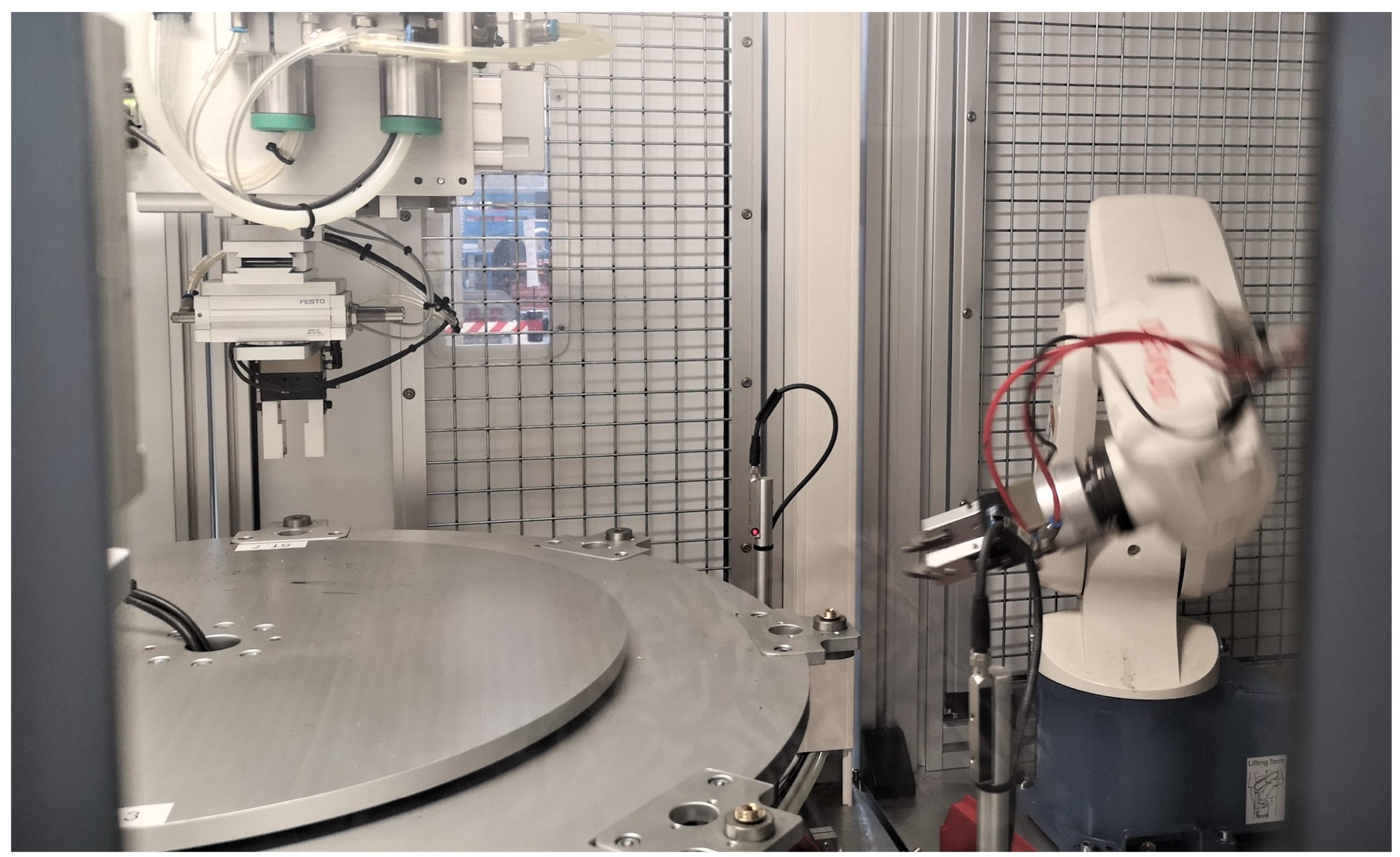

The new entry in A&B’s machinery is a 100% automatic selection / control and assembling machine – made for the inspection and assembly of components produced for very important client of ours.

What once used to be done manually – such as the assembling process – nowadays, with this custom-made machine, selection and assembly are carried out by the same machine resulting in a lower error rate and an improved time saving performance. This kind of machine have built-in robotic arms that pick and place components for checking operations through laser and cameras, applying fats and o-rings assembly.

As the world changes A&B keeps on growing together with its suppliers and clients.

A&B is not just a precision turning company anymore: it has grown into a mechanical company that develops tailor-made solutions.

Curious about it? Do you have an assembly component where you’d like to receive a quotation?

There are only two conditions to follow in order to make your request:

A&B is willing to undertake the investment costs with the only request that clients are willing close yearly purchasing contract (3-5 years long);

Assembly products must be composed by at least one turned component;

Send your inquiry and technical drawings to receive a quotation.

Stay modern, stay active.

A&B Team