A&B’s new Citizen L 12 VII°

A&B opened 23 years ago and for many years has worked with multispindle machines only. After many years of experience, A&B, within a vision of growth and R&D, has done its best to offer solutions and services that could satisfy clients with a variety of needs.

It is by bigger productions of 50k+ up to MLN pieces that companies can benefit from multi-spindle machines potential and reach the best cost effectiveness.

But what happens when a client asks for samples or prototypes to test new products? How to handle complex geometry components when a multispindle machine is just not enough?

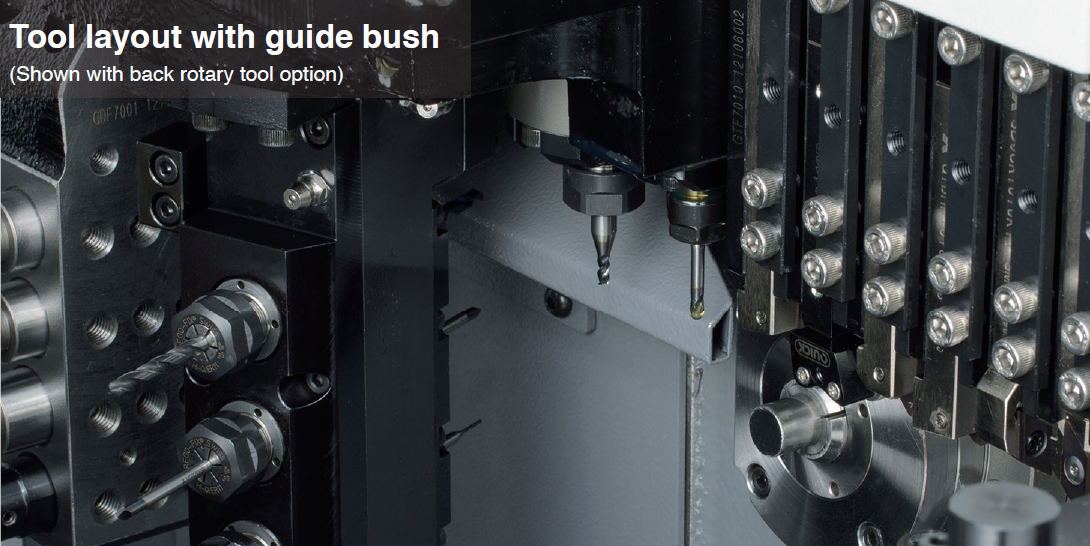

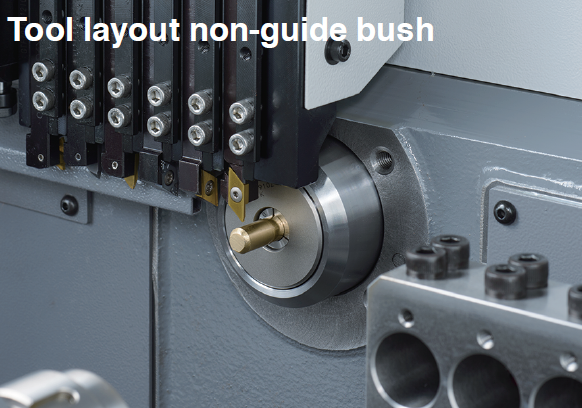

This is when our new Citizen L12 VII° comes into play: a sliding headstock type CNC automatic lathe with switchable guide bush which deliver the best performances by small diameter applications.

Its setup is simple on both modes: the regular guide bush can be used for long or slender parts, the non-guide bush mode can be used for short parts to save material wastage.

Fast and versatile on smaller parts, way more competitive than a mulstispindle machine, it’s perfect for the production of longer components thanks to its moving headstock.

A&B has recently acquired this new machine and it’s been serving A&B’s clients for the past months. Curious about it? Want to know what components are the right fit for this machine?

Send your inquiry and technical drawings to find out!